October 29, 2018

Wirelessly Networking a Compressed Air System

SHARE THIS POST

Wirelessly Networking a Compressed Air System

If you take a good look at a pair of Quincy QGV-50’s that were recently installed at a local shipping depot, you will see all of the things you would expect to find on this premium air compressor. It features robust mechanical parts (the airend carries a 10-year warranty) and a well-designed acoustic cabinet that keeps sensitive electronics separate from the heat producing parts of the machine. Quincy’s Q-Controller is the brain that keeps this machine running. Built into that Q-Controller is the capability to network with other air compressors. What you will not see are network cables.

Compressed Air Networking Benefits

Compressed air networking yields many benefits; automatic rotation of the lead machine, balanced run time across machines, automatic back-up in the event of a machine fault, and, in the case of Quincy’s Q-Controller, a network algorithm that runs the machines in the most energy efficient way possible. The main drawbacks to networking have traditionally centered around getting cables between the machines. The laborious task of finding a good sub-contractor to run conduit and cables between the machines brings a whole set of problems with it. Will they pull the correct cables? Will their conduits look nice? Will they leave a finished product you can proudly put your name on? These problems, and many more, disappear if there is a wireless solution. So, the C.H. Reed Service Department set out to find one.

Wireless CAN Module – The Wireless Networking Solution

The Quincy Q-Controller networks via a communication protocol called CAN (Controller Area Network). This is a common protocol in use throughout the industrial world and in the automotive industry. We began our search for a wireless CAN module by laying out a few “must haves”. We settled on 4 things:

- Made for harsh, industrial environments.

- RF (radio frequency) noise resistant.

- Easily configurable in the field.

- Top notch technical support readily available.

Air compressors typically live in hot, dirty, sometimes very humid environments, and there are usually other machines in the room with them. The starting and stopping of other equipment and the flow of various other gases and liquids through pipes in the room can create a fair amount of radio frequency noise. We needed a module tough enough to handle anything we threw at it.

Magnetek Enrange WIC-2402 Wireless CAN Module

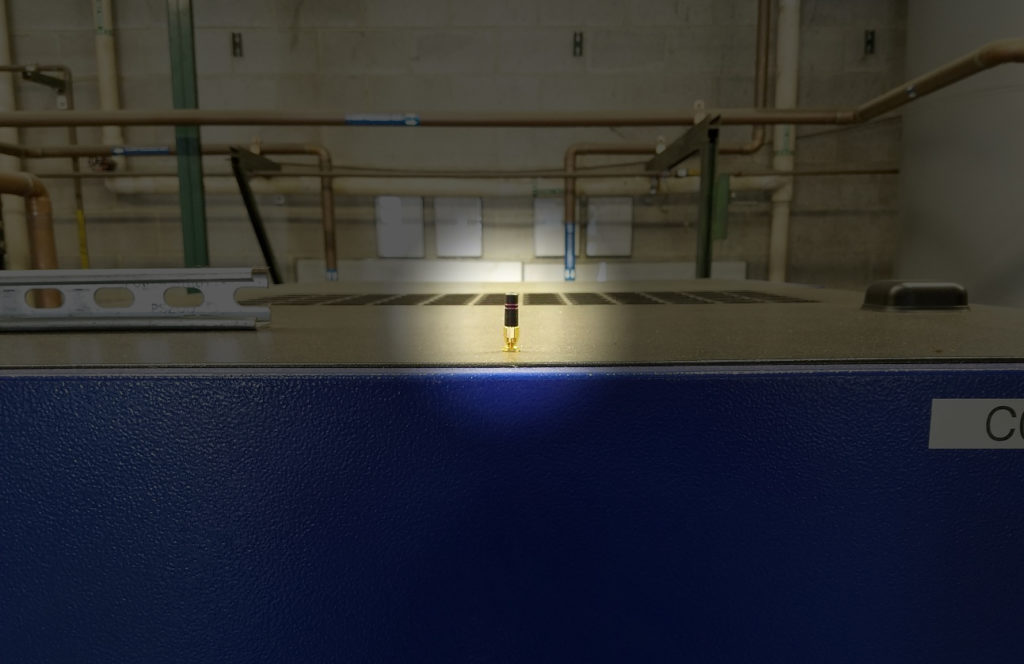

After reviewing many different wireless CAN modules, we settled on Magnetek’s Enrange WIC-2402 Wireless CAN Module. This robust CAN module is designed for use on cranes, boom trucks, and other heavy equipment. Most other modules we looked at were made for use in climate-controlled server rooms. The WIC-2402 was made to be mounted on heavy equipment so we were confident it could stand up to the worst of air compressor rooms.

One of the other aspects we considered when reviewing wireless CAN modules was the ability to change parameters “on the fly”. It can be rather frustrating to want to change a simple parameter on a piece of equipment and you have to hold this button for 5 seconds, while pressing this other button to access the menu, etc. The WIC-2402 is very easy to modify in the field. It connects to a PC via USB wiring, and the RCP software is very simple to use. This was far more user friendly than the others we had looked at.

Lastly, before deciding on the WIC-2402, we called the technical support line and asked a number of questions. We wanted to be sure that there was a real technician on the other end of the phone, not someone reading from a script. We were not at all disappointed with the tech support from Magnetek. Every question was answered quickly and succinctly. This gave us confidence that any issues we came across in the field would be handled easily with one phone call.

The End Result

This was our first Beta test site using a wireless networking solution. It has been operating trouble free for over 10 months now. There are several other pieces of equipment in the room with the compressors, including boilers, large refrigeration units, and electrical switch gear. Numerous pipes crisscross the room, carrying all manner of liquids and gases. There were a few instances during the winter when the overhead garage doors were left open and some of the other equipment froze up. Despite all this, our air compressors never experienced a network interruption.

For more information on the Magnetek Enrange WIC-2402 Wireless CAN Module, or our many other compressed air wireless solutions, contact controls@chreed.com.

Search

Categories

Get a consultation

Related Posts

The 3 Distinct Advantages of Hydraulic Powered Pumps

Recently, C. H. Reed helped a major printing operation install a new ink pumping system. The new system needed to transfer four colors of high viscosity, heat-set ink to their three presses, drawing the ink from multiple 5,000…

Simple Ways to Reduce Waste in Your Spray Finishing System

In today’s demanding manufacturing landscape, it can be convenient to adopt a “cut-costs-at-all-costs” mentality, justifying questionable means for the sake of leaner production, a lower bottom line and increased profitability. Regrettably, those efforts can interfere…

What You Need to Know About Air-Powered Pressure Washers

Pressure washers are great solutions for your average cleaning applications, but what tool do you turn to for your more challenging applications? There are many instances where it is simply impossible to use a traditional…