Clean-up generates the largest percentage of hazardous waste in all industrial paint finishing operations. Solvent is used to flush excess paint out of industrial paint spray equipment. The amount of solvent required to clean the equipment depends on how much material is trapped within the system. Typically, the amount of solvent used to flush a system is roughly 3x the volume of the waste material trapped within. When changing the color of material within a system, the amount of solvent used can be up to 6x the volume of the waste material.

In most operations, a 55-gallon drum of waste has less than 10% of actual paint waste. (Even if it was double in paint waste, you would still have 40-gallons of recyclable solvent in the drum.) In this case, you’re throwing away money. But, there’s a solution.

Solvent recovery still recyclers are the cleanest, safest, most reliable and cost-effective way to recover and recycle waste in the industry. Solvent distillation recyclers are engineered to greatly reduce your solvent purchases and your hazardous waste generation; substantially reducing material costs along with disposal costs.

How Solvent Distillation Recyclers Work

Solvent distillation recyclers remove paint waste, pigments, solids, and other impurities from used solvents such as lacquer thinners and reducers. Through the distillation process, the used solvent is boiled to a vapor and then condensed back into a liquid, leaving the contaminant behind in the tank for recovery. Solvent recyclers have a tank with a specially designed bag liner, which contains the left-behind residues, that can easily and efficiently be removed and disposed of. The collected solvents can be up to 99% pure; greatly reducing the amount of new solvent you must purchase and minimizing hazardous waste streams. The clean, distilled solvent can be used repeatedly with virtually no loss of cleaning effectiveness.

The Benefits of Solvent Recyclers

Economic benefits: Solvent recyclers reduce your liquid waste disposal expenses. The clean, distilled solvent can be used over and over again, so you spend a lot less money on unnecessary solvents purchased.

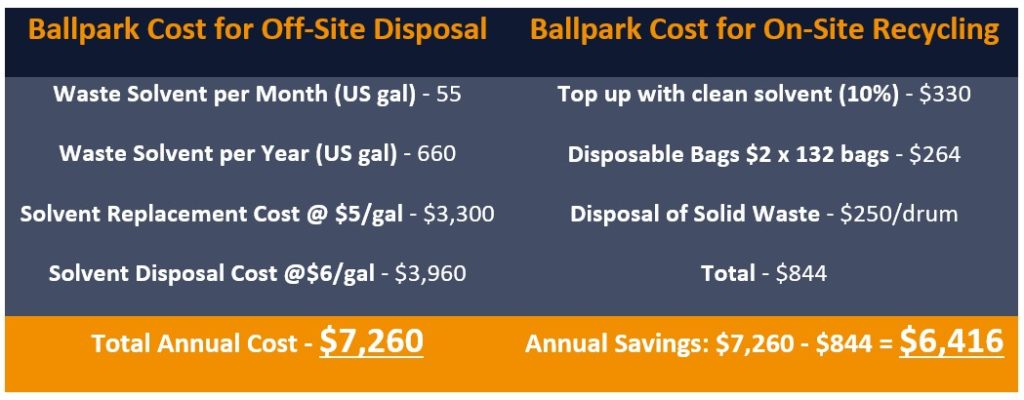

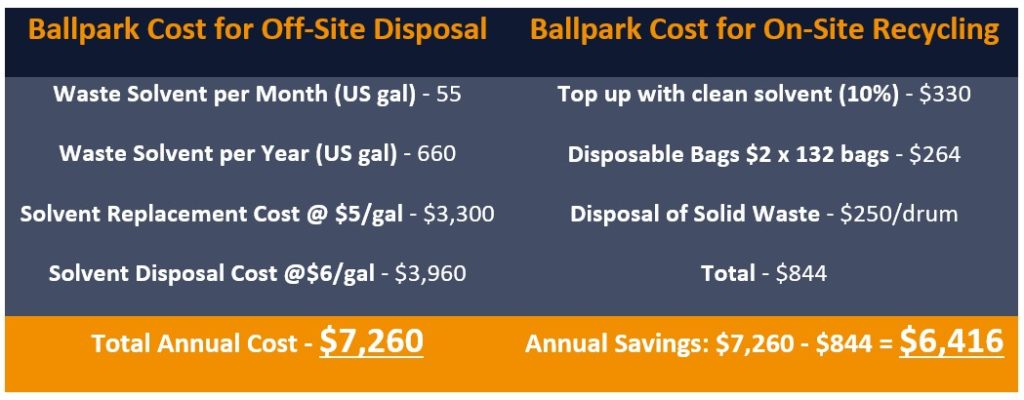

Sample cost analysis based on a company that generates one 55 gallon drum of waste per month:

- Environmental benefits: Simply put, we all have a moral obligation to reduce the generation of hazardous waste to protect the environment. Recycling and recovering your hazardous waste (solvent) eliminates the need for disposal; providing a “greener” painting operation with reduced operating expenses.

- Regulatory compliance: Solvent distillation recyclers help manufacturers improve their “waste generation status” with environmental agencies and help local governments achieve waste reduction goals.

C.H. Reed incorporates both Uni-ram and BECCA Solvent Distillation Recyclers into our solutions. Both brands provide a clean, safe, reliable, and cost-effective way to recover and recycle solvent waste for paint finishing operations. To learn more about solvent recyclers and reclaim systems and how they can help you save money while reducing your footprint, contact us today!