February 12, 2020

New Case Study: 2K Mixing System Upgrade for Machinery Manufacturer

SHARE THIS POST

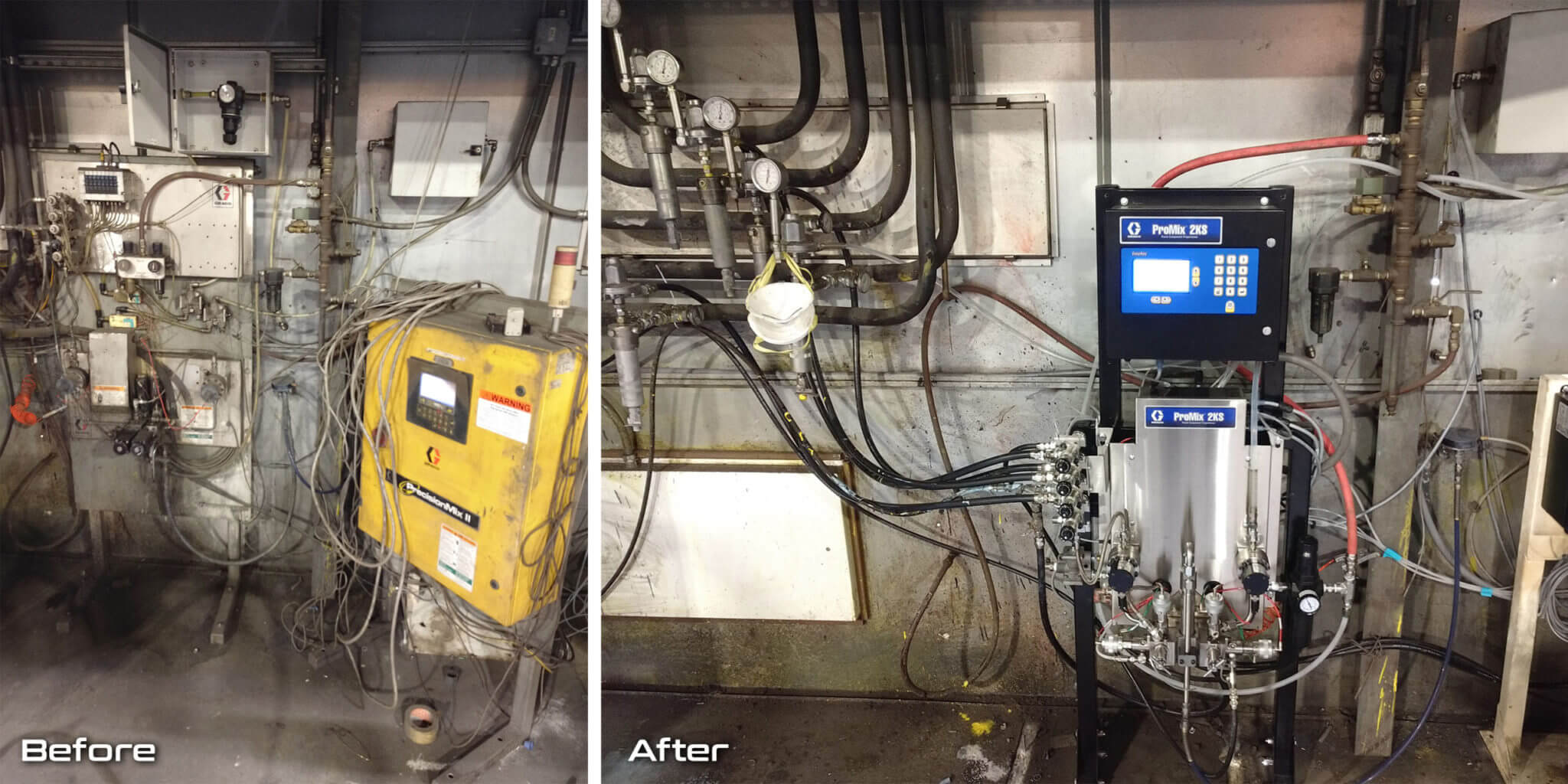

The benefits of Preventative Maintenance Programs are numerous. They enhance the productivity of the equipment, reduce overall operating costs, reduce downtime, reduce emergency repairs and greatly extend your equipment’s life expectancy and value of your investment. In 1999, a key partner invested in multiple Graco Precision Mix II units to meet their production and quality goals. At the time, these units were the benchmark for electronic proportioning with the highest level of technology and control.

For 20 years, C.H. Reed has provided a customized Preventative Maintenance Program on these units with authorized, factory-trained service technicians and OEM parts. As a result, the machines have run to the same standards as the day they were put in.

However, during a recent yearly audit we conduct for our customer on their paint finishing requirements and goal for continuous improvement, we identified that these units were obsolete. Although working well, hard parts pricing had drifted higher due to lower demand and, most importantly, the software and some electronic components were no longer supported; creating a serious risk should any of those components fail. As a worldwide leader in their industry, our end-user decided it would be best to invest in equipment upgrades to eliminate potential risks to their position.

C.H. Reed worked closely with them on this equipment upgrade and plan to install. The latest generation Promix 2KS was selected as a replacement. The technology and design enhancements over the Precision Mix II make the Promix 2KS a great, flexible machine and platform. We were able to upgrade all machines without shutting down any operations during the removal of the old units and installation of the new. Coupled with a Preventative Maintenance Program to support, the end-user can look forward to years of trouble-free operation, lower cost of ownership, and enhanced finishing quality. Lastly, the risk of unsupported equipment has been eliminated.

To learn more about customized planned maintenance programs or how C.H. Reed can help you with your paint finishing process, simply contact us today.

Search

Categories

Get a consultation

Related Posts

The 3 Distinct Advantages of Hydraulic Powered Pumps

Recently, C. H. Reed helped a major printing operation install a new ink pumping system. The new system needed to transfer four colors of high viscosity, heat-set ink to their three presses, drawing the ink from multiple 5,000…

Simple Ways to Reduce Waste in Your Spray Finishing System

In today’s demanding manufacturing landscape, it can be convenient to adopt a “cut-costs-at-all-costs” mentality, justifying questionable means for the sake of leaner production, a lower bottom line and increased profitability. Regrettably, those efforts can interfere…

What You Need to Know About Air-Powered Pressure Washers

Pressure washers are great solutions for your average cleaning applications, but what tool do you turn to for your more challenging applications? There are many instances where it is simply impossible to use a traditional…