Air Compressors, Fluid Transfer, and Vacuum Solutions for Food Processing and Manufacturing

Classified under the 311 3-digit NAICS code, Food processing and manufacturing refers to a series of techniques and processes implemented to convert raw food materials and ingredients into finished edible products. These steps can include one or a combination of methods such as washing, freezing, packaging and pasteurizing.

Air compressors play a significant role in food manufacturing and processing industries. Compressed air assists in everything from food mixing and packaging to fluid pumping and air infiltration. Some specific examples include:

- Sorting raw ingredients as they enter a factory or plant

- Slicing and peeling fruits and vegetables such as apples, onions and carrots

- Completing sanitation tasks such as washing down packaging machines and cleaning packages before filling

- Forming, filling and sealing cartons

- Cutting and shaping food products

- Using blow-molding and other techniques to create specialized packaging

- Blowing crumbs away from baked goods

- Vacuum-sealing packages containing food products (vacuum pumps)

- Freezing products before they ship

- Propelling liquids to ensure even distribution throughout a package

Regardless of the application, high-quality equipment must generate clean compressed air to minimize the risk of contamination.

How are Air Compressors Used in Food Manufacturing?

How are Air Compressors Used in Food Manufacturing?

Air compressors are used in endless applications in food and beverage manufacturing. From sorting and moving products down a production line, to cutting and peeling fruits and vegetables, filling baked goods, snacks, and pastries, helping cool down products, helping mix products, creating packaging, cleaning and filling packaging, powering nitrogen generation systems, and helping maintain a clean environment.

How are Pumps and Fluid Handling Systems Used in Food Manufacturing?

Fluid transfer equipment, such as sanitary diaphragm pumps and packages, bin and drum unloaders, piston pumps, and sanitary pressure washers play important roles in food manufacturing and processing. Food manufacturers rely on sanitary fluid transfer equipment to integrate ingredients like concentrated fruit juices, different kinds of sauces, pastes, starches, wines, food-grade oils, jams and jellies, and much more into their process. A lot of these ingredients are purchased in large bins and totes. Bin and drum unloaders are utilized to transfer the ingredients to fillers and mix kettles - helping reduce costs by improving material evacuation rate, time, and efficiency. With sanitary fluid transfer solutions for a wide range of viscosities, C.H. Reed can help you move any type of material quickly, cleanly, and safely.

How are Vacuum Pumps Used in Food Manufacturing?

Vacuum pumps are also often utilized in food and beverage industries. A common example is vacuum packaging of meats, fish, cheese, etc. A plastic bag is typically used for packaging these types of products. Once the product is ready for packaging, it gets placed into a machine, the lid is closed, and the air is removed via a vacuum pump. A heat seal inside the chamber will then seal the bag.

Another example where vacuum is used is meat preserving. In many slaughterhouses, vacuum pumps are utilized to separate meat from other internal components of the

animals. Another preserving example where vacuum is utilized is modified atmosphere packaging, where the evacuation of air and the injection of a neutral gas, like nitrogen, takes place. The package is then sealed and ready for the shelf.

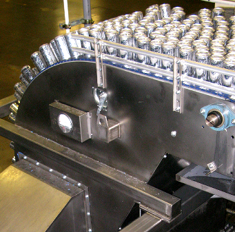

One last example of how vacuum pumps are used in food and beverage manufacturing are on canning lines. Beverage manufacturers use vacuum pumps to hold down aluminum cans during different stages of the filling process. Since aluminum is non-magnetic, vacuum pumps hold the cans tightly down on the assembly line.

C.H. Reed Provides Compressed Air, Fluid Transfer, and Vacuum Solutions for Food Processing and Manufacturing Companies

C.H. Reed has what you need to improve the efficiency and quality of your food manufacturing operations. We feature oil-free air compressors from Quincy that deliver clean, contaminant-free compressed air wherever you need it in your food processing applications. Our fluid transfer partners, Graco and ARO, offers an assortment of food-grade fluid transfer equipment, double diaphragm pumps, bin and drum unloaders, piston pumps, and washers that we integrate into our solutions.

As a full-service equipment provider for the food manufacturing industry, we offer complete support for all the products we sell. We'll install, maintain and repair your system and provide training for your crews if needed. As your trusted business partner, we'll take the time to get to know your operation and deliver the best solutions based on your needs and budget.

If you operate a food manufacturing or processing operation in PA, MD, DE, VA, WV, OH, or southern NY, reach out to C.H. Reed today. We'll be happy to help you explore all your air compressor and fluid transfer needs to find the right solution for you.