July 28, 2016

C.H. Reed Engineered Systems

SHARE THIS POST

C.H. Reed’s Engineered Systems Department develops and configures non-standard, tailored solutions for a wide-ranging variety of applications throughout all three C.H. Reed product groups:

- Compressed Air Group

- Assembly Tool & Material Handling Group

- Paint Finishing & Fluid Dispense Group

The department’s capabilities range from simplistic applications, such as tank-mounted refrigerated air dryers, to multifaceted engineered projects, like three-component fluid mixing or programmable assembly tooling on manufacturing production lines.

The overall goal of the Engineered Systems Department is to facilitate the installation of innovative systems for both new and existing customers with the end result of increased communications, productivity, ergonomics (worker safety), energy efficiencies, environmental benefits, and maintenance cost reductions.

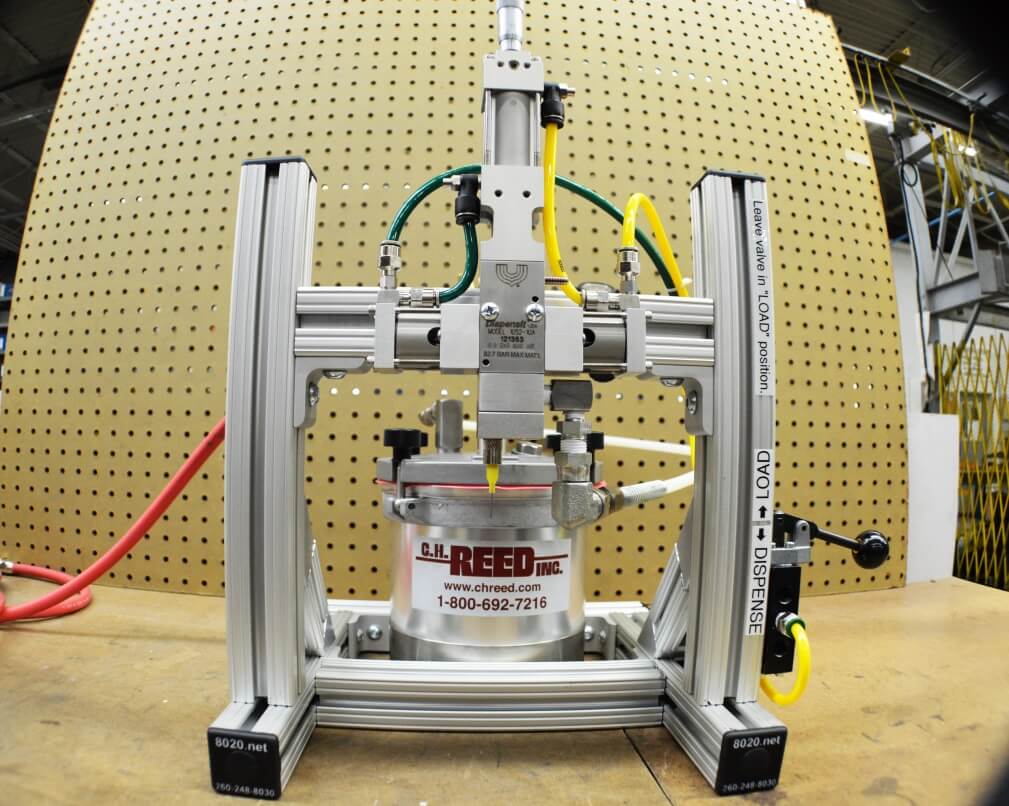

Case Study: This customer needed a custom solution for an application that, in the end, could accurately portion and distribute small, precise shots of liquid. The Engineered Systems Team at C.H. Reed fabricated a custom Graco 1052 Dispensit Valve with positive displacement metering rod. The Graco 1052 Dispensit Valve is a pneumatically-controlled valve with micrometer adjustable dispense volumes for accurate, repeatable shot dispensing. The liquid flows through the (yellow) needle with a rate that is adjustable in both pressure and volume.

How It Works

Fill Mode: The shuttle spool is positioned to open the inlet port while isolating the outlet port. Material enters the metering chamber as the metering rod retracts.

Dispense Ready: The spool is positioned to connect the metering chamber to the outlet port providing a material flow path to the dispense needle(s). The shuttle valve also obstructs the material flow path from the inlet port.

Dispense Mode: The metering rod is extended into the metering chamber to displace the material. Total volume dispensed is a function of rod size and shot size setting from micrometer stroke adjustment. Upon completion of the dispense stroke, the metering rod and spool shift back to the reload position and starts the process over again, delivering the exact amount of liquid each and every time.

Conclusively, this customer now has full control over the dispensed amounts of liquid, as it may vary during different project ventures. They simply adjust the micrometer setting to the exact gram needed for their application(s) and can trust that they will receive consistent, accurate results.

For more information on C.H. Reed’s Engineered Systems Department or if you would like to schedule an appointment for a complete analysis of your system, contact us today!

Search

Categories

Get a consultation

Related Posts

The 3 Distinct Advantages of Hydraulic Powered Pumps

Recently, C. H. Reed helped a major printing operation install a new ink pumping system. The new system needed to transfer four colors of high viscosity, heat-set ink to their three presses, drawing the ink from multiple 5,000…

Simple Ways to Reduce Waste in Your Spray Finishing System

In today’s demanding manufacturing landscape, it can be convenient to adopt a “cut-costs-at-all-costs” mentality, justifying questionable means for the sake of leaner production, a lower bottom line and increased profitability. Regrettably, those efforts can interfere…

What You Need to Know About Air-Powered Pressure Washers

Pressure washers are great solutions for your average cleaning applications, but what tool do you turn to for your more challenging applications? There are many instances where it is simply impossible to use a traditional…