January 14, 2020

Quincy Compressor’s QOF 75-200 HP Oil-Free Screw Compressor

SHARE THIS POST

In October of 2018, Quincy Compressor launched their new QOF 75-200 HP line of oil-free rotary screw compressors to the market. The QOF 75-200 HP line delivers outstanding performance, dependability, and sustainability while minimizing the total cost of ownership. Built to perform in some of the harshest environments, these oil-free screw compressors will keep your production running smoothly.

What makes the Quincy QOF 75-200 HP Oil-Free Series Reliable, Efficient, and Easy to Service?

- The inlet filter is machine-mounted, highly efficient, and will minimize intake loss.

- Quincy’s advanced Q-Control monitoring system provides machine performance statuses, service indications, alarms for malfunctions, and safety shutdowns. All the monitoring and control functions are on one interface, delivering vast communication possibilities. Lastly, integration is possible in many control systems. C.H. Reed’s Controls Group can help you with this.

- Quincy’s high precision gears offer a long lifetime, low transmission losses, and low noise and vibration levels.

- Quincy’s superior element bearings are highly stable under varying load conditions, are adjustable to load changes, don’t need pre-lubrication/stabilization time, and are joint-developed with top-ranked global bearing supplier, SKF.

- The water separator’s labyrinth design efficiently separates condensation from the compressed air protecting downstream equipment.

- Quincy Compressor’s rotors are world-class, delivering 100% oil-free air with ultimate efficiency; thanks to their superior rotor coating and element cooling jackets. These rotors are engineered and assembled with precision and can sustain speeds far below critical speed.

- The aluminum alloy fin cooler reduces dust accumulation and filth blockage.

- The IE3 high-efficiency motor is totally enclosed – IP55 TEFC protection and Class F insulation.

- The integrated fan assembly has low energy consumption for highly efficient cooling.

High-Quality, Oil-Free Air for a Variety of Critical Applications

The Quincy QOF 75-200 HP Series provides a long, trouble-free life at the lowest possible operating cost for a variety of critical, oil-free applications:

- Food and Beverage: Food and beverage manufacturers rely on oil-free air compressors for fermentation, packing, air-filling, transport, filling & capping, cleaning, instrument air, etc. The air that performs these tasks must be oil-free so there’s no risk of contamination.

- Electronics: The electronic industry depends son oil-free air during the production of electronics to guarantee precision processing. If the air is impure, issues like poor performance, short lifetime, and product reworks can occur.

- Pharmaceutical: When pharmaceuticals are produced, there are strict requirements and regulations that need to be met. 100% oil-free air must be used to prevent any risk of contamination is processes like fermentation, air-filling, tablet packaging, canning, automatic production, etc.

- Oil-free air is crucial in a lot of other industries as well. This includes, but is not limited to, automotive (tier 1 and 2), chemical manufacturing, universities, hospitals, gas separation, power generation, textiles, etc. (Also, heavy compressed air consumers, where centrifugal compressors are often used, will often install oil-free rotary screw compressors as trim machines since their compressed air system is already oil-free.)

In all these critical manufacturing environments, contamination by even the smallest amounts of oil can result in costly production downtime and product spoilage.

Quincy QOF 75-200 HP Oil-Free, Variable Speed Drive Compressors Increase Energy Savings

Quincy QOF 75-200 HP Oil-Free, Variable Speed Drive Compressors Increase Energy Savings

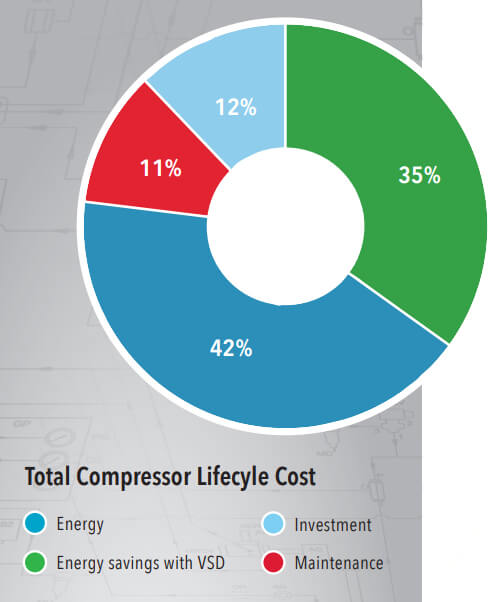

Quincy’s QOF 75-200 HP line of oil-free compressors come in both fixed-speed and variable-speed drive options. When talking about the “total lifecycle cost” of an air compressor, you need to account for three main factors; Initial investment for the equipment, maintenance, and the electricity it takes to run the equipment. Roughly 80% of the total lifecycle cost of an air compressor will be spent on energy consumption. This means that 40% of a plant’s electricity bill goes to the generation of compressed air.

To help with these energy costs, Quincy’s QOF Series has variable speed drive options that deliver energy savings of up to 35%. The QOF’s variable speed drive technology closely follows the plant’s air demand and adjusts the motor speed accordingly. This results in the total lifecycle cost of the compressor to be cut by an average of 22%. Additionally, lowered system pressure with a variable speed drive dramatically minimizes energy usage across your production.

Quincy Compressor Q-Control Advanced Monitoring, Controls, and Networking

Quincy’s Q-Control monitoring system combines the latest controller technology and software to deliver a broad range of user benefits that improve uptime and reliability:

- Easy-to-use interface with full-color 5.7” display

- Networking capable of up to 6 compressors

- Online visualization via ethernet connection

- Real-time trending on the controller screen

- Daily and weekly organizer

- Dual pressure band

- Graphic service plan indicator

- Pre-warnings

- Predictive graphic service plan

- Remote monitoring/cellular connectivity with Q-Connect

- Shutdown and maintenance schedules

- Remote pressure sensor (optional)

- Etc.

C.H. Reed’s Oil-Free Compressed Air Solutions Across the Mid-Atlantic Region

With decades of providing compressed air solutions and services to businesses throughout Pennsylvania, Maryland, Virginia, West Virginia, Ohio, southern New York, and Delaware, our compressor specialists can help your facility find and integrate the correct oil-free compressed air system for your specific application(s), regardless of industry. If you would like to learn more about Quincy Compressor’s QOF 75-200 HP series of oil-free screw compressors, simply contact us to start the conversation.

Search

Categories

Get a consultation

Related Posts

The 3 Distinct Advantages of Hydraulic Powered Pumps

Recently, C. H. Reed helped a major printing operation install a new ink pumping system. The new system needed to transfer four colors of high viscosity, heat-set ink to their three presses, drawing the ink from multiple 5,000…

Simple Ways to Reduce Waste in Your Spray Finishing System

In today’s demanding manufacturing landscape, it can be convenient to adopt a “cut-costs-at-all-costs” mentality, justifying questionable means for the sake of leaner production, a lower bottom line and increased profitability. Regrettably, those efforts can interfere…

What You Need to Know About Air-Powered Pressure Washers

Pressure washers are great solutions for your average cleaning applications, but what tool do you turn to for your more challenging applications? There are many instances where it is simply impossible to use a traditional…